Processes

To meet your sanitary processing needs, RWS offers expertise in heat transfer, mixing and blending, separation technology, cleaning and recovery, fluid handling and homogenization, tanks and silos, and automation and control.

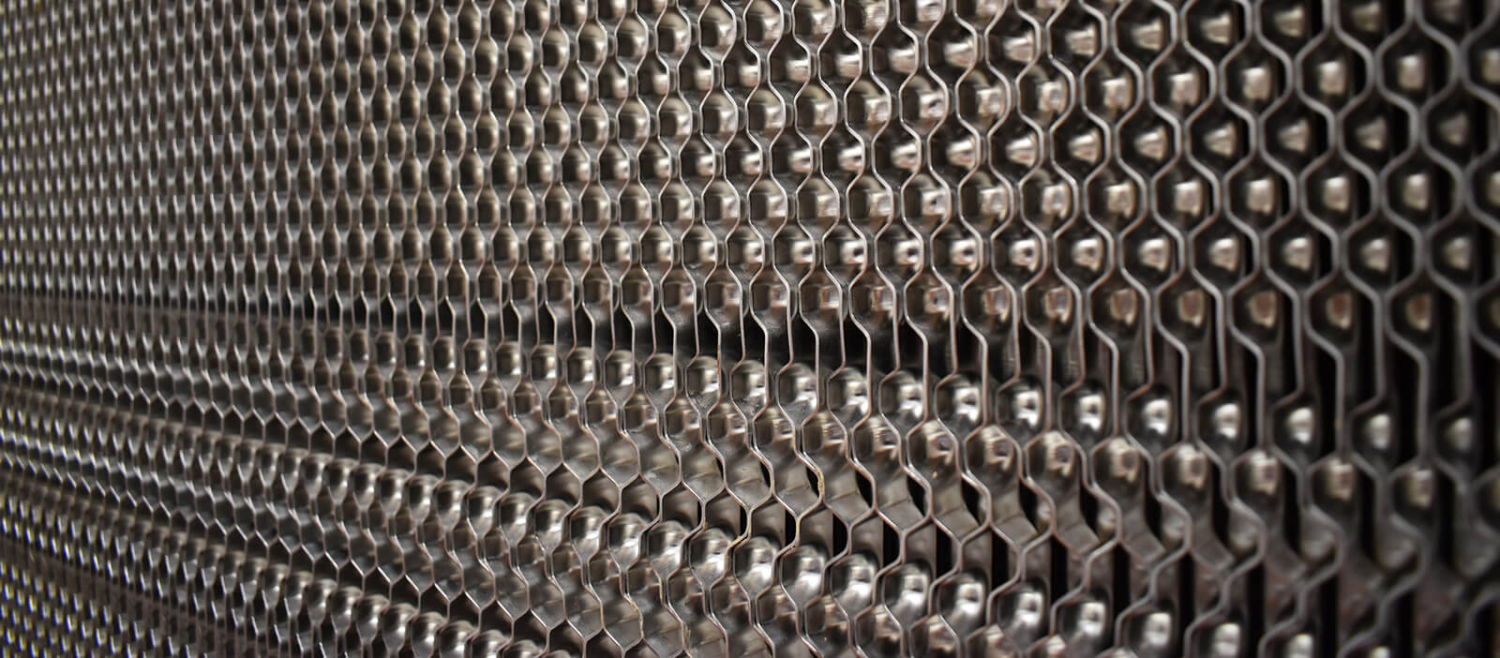

Heat Transfer

Creating and obtaining an optimized thermal process within your plant is at the core of RWS’ expertise. From traditional high-temperature, short-time (HTST) pasteurization, to direct and indirect ultra-high temperature (UHT) sterilization, RWS offers the solutions you require for optimal processing. We are also experts in designing, furnishing and commissioning ESL and Aseptic processes for a wide variety of product, as it is our specialty. We provide advanced thermal process systems that are fully compliant with the latest regulations and guidelines, as well as stand-alone heat transfer equipment, such as plate, tubular, shell and tube heat exchangers to meet many processing needs. RWS’ custom skid fabrication facility can also fabricate heat transfer-modular process skids for a wide variety of sanitary applications.

Mixing and Blending

Our engineering professionals at RWS can design, furnish and install your most demanding mix and blend processes. Our systems are designed to incorporate powder-into-liquid solutions quickly and efficiently while minimizing labor for material handling of ingredients. In addition, RWS supplies a large variety of mixing equipment from leading OEM’s, and we will customize a mix/blend room and/or modular skid specific for your needs. Let RWS develop a mix/blend system for your next application and see what years of expertise can do for your application.

Separation Technology

RWS designs high-quality, state-of-the-art separation systems. These include plate and tubular evaporation systems, distillation technologies, Ultra and micro-filtration, cream separation and others. RWS can provide a separation system to meet your exact requirements in many different sanitary processing industries. Contact us to discuss your next application.

Cleaning and Recovery

Understanding your unique cleaning and sanitizing needs is a critical part of establishing a successful processing system. Ensuring the integrity of your plant sanitation and minimizing your maintenance issues are vitally important concerns for your daily operation. RWS is ready to address these needs for you with our custom-designed CIP (clean-in-place) and COP (clean-out-of-place) technologies. We understand the magnitude of plant sanitation, how it impacts your operational costs and company reputation, and how it ensures the health and safety of the consumer. We take this responsibility seriously and are experts in the design and manufacture of customized sanitization solutions. RWS’ cleaning designs comply with all PMO and regulatory requirements. As part of our large portfolio of equipment, systems and services, RWS has the skills and expertise to design, manufacture, install, and properly automate a cleaning system for your operations.

Fluid Handling and Homogenization

Another RWS specialty is the management of your fluid processing via a wide variety of pumping applications, homogenization, tank and silo storage, and simple to complex valving arrangements. We offer the latest in fluid handling technology, equipment and design to maximize your plant performance throughout each step of the process. From modular valve skids to custom pumping solutions, RWS can help you manage the transportation and valving of all your fluid handling needs. Let our experts work with yours to offer the best solution for standard fluid handling, ESL, or Aseptic environments.

Tanks and Silos

At RWS, our experience in designing, furnishing, installing and controlling the flow of product and ingredients throughout your tank silo and storage systems is a specialty. We are experts in the selection of the right tank sizing, agitation and design for your application in dairy, beverage and personal care products, and add great value to your project. From large, multi-tank silo farms to specialty tanks to ESL and Aseptic storage designs, let RWS assist with your next project and see the difference we make.

Automation and Control

At RWS, we are proud of our UL-certified panel fabrication shop located at our headquarters in Roscoe, IL. Our team of design engineers and fabricators are at your disposal in the manufacture of customized control panels. In addition, our teams of field engineers are at your disposal to service, install, design, program and troubleshoot the latest in automation and control from all leading vendors in the field. RWS is a Master Provider for Rockwell Automation, and we specialize in all platforms of automation and control by using the latest technology available. At RWS, we value and respect your choices in automation platforms and work with the best in the industry. Our teams are well trained and experienced in numerous platforms, including Ignition, Wonderware, Control Logix, Rockwell Automation and many others. We also provide and offer value-added expertise in process control instrumentation from all leading OEM’s.